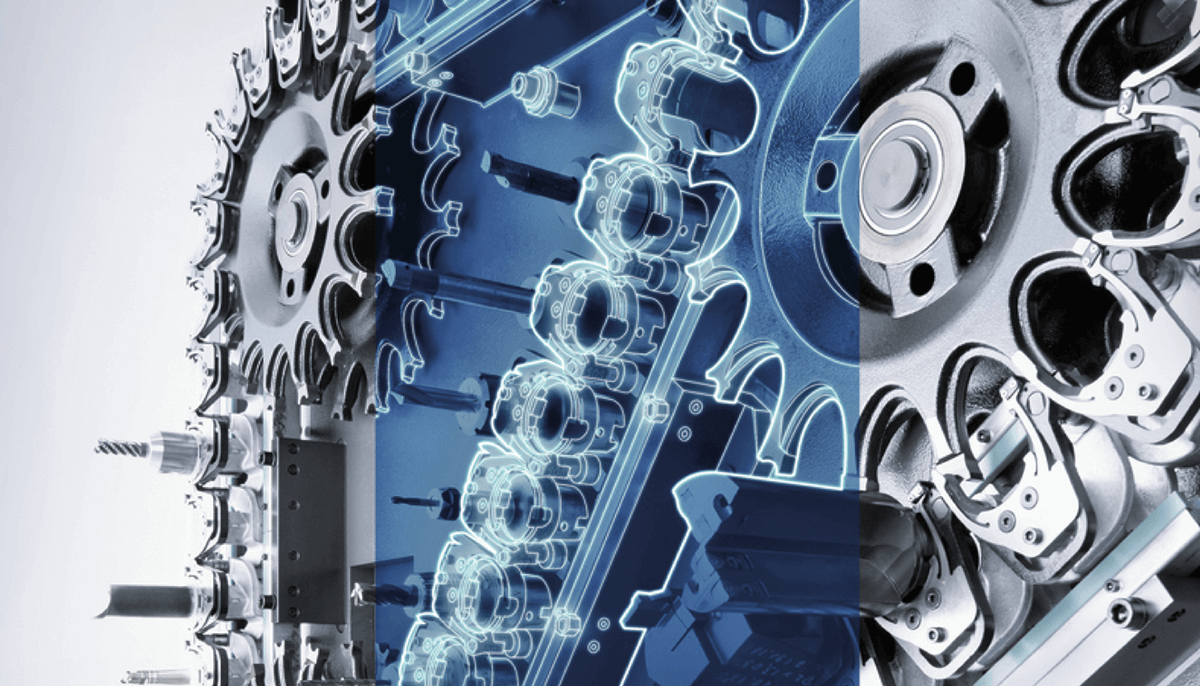

The FFG Group therefore offers users the technology of Power Skiving on different machine concepts (MODUL gear cutting machine skiving with alternative machining processes, HESSAPP vertical turning machine for disc-type components with swivelling workpiece axis or the BOEHRINGER shaft turning centers with optional tool spindle). This eliminates a large part of the loading and unloading of the components, the intermediate transportation and the quality losses due to clamping faults in the subsequent machining processes. The main advantage of the above-mentioned process integration is that the components can be finished without or at least with fewer downstream machines. In recent years, skiving has made a quantum leap in industrial manufacturing with the availability of modern control technology for spindle synchronization, tool technology for high-performance cutting and a machine structure that meets the high demands for rigidity and dynamics. While the traditional alternative processes for gear machining such as broaching, gear shaping and gear hobbing are mainly used in technology-specific special machines, gear skiving can be applied on special machines and on modern 5-axis machining centers.

The smaller the axis cross angle, the closer towards the interference contour can be machined. 30 to 50 %) in comparison to the likewise flexible gear shaping and the ability to apply the gearing close to an interfering contour (workpiece shoulder). Significant for the skiving process is the short machining time (approx. The cutting speed results from the rotational speeds of tool and workpiece in relation to the axis cross angle. In this way the tooth space is “peeled out” of the workpiece in several cuts. By superimposing a feed motion, both add to the movements to the feed speed and guide the cutting edge along the workpiece axis. With the coupled rotation of workpiece and tool, a relative movement of the cutting edge in the tooth space is thus created. The skiving process is characterized by the tool and workpiece axes arranged in a certain relationship to each other – the axis cross angle. In addition to traditional gear machining processes such as hobbing, gear shaping and broaching, skiving is a continuous machining process for soft and hard machining of internal and external gears. “Power Skiving” makes a significant contribution to each of these aspects.

As with all manufacturing technologies, quality, cost optimization, flexibility and productivity are the top issues. The use of planetary gears for reduction or as a differential in the drive system also increases the demand for internal gears. With e-mobility, a market is now growing which demands high precision (low running noise), high power transmission (torque and speed) from the product and equally high product flexibility in volume production.

Power skiving dmg products series#

The NEOPS 200 and NEOPS 400 offer manufacturers a leading combination of technology and productivity at an affordable price with domestic support.Like electric mobility, the technology of power skiving has been known for more than 100 years and, with the availability of 5-axis machining centers, has found its way into individual and series production due to its convincing process flexibility. Key optional features include automatic tool changer, deburring, cutting tool resharpening, and automatic loading / unloading. The machines use high quality components such as direct-drive torque motors for the work and cutter spindles, FANUC 0i MF CNC, and precision linear scales. The NEO Power Skiving line includes the model 200 and model 400 with capacities for parts up to 420 mm (16.535”) diameter and a pitch rating of 4 module (6.35 DP). This is achieved with a continuous process where the cutting tool is constantly producing small cuts, whereas traditional shaping has unavoidable idle backstrokes that reduce productivity.

Consequently, NEO Power Skiving allows manufacturing gears with a game-changing level of productivity and profitability. Compared to shaping, power skiving offers a gear tooth generating operation that is a fraction of the time. Internal or external spur or helical gears are candidates for power skiving - in particular, those that may traditionally require shaping due to clearance requirements. “Gear manufacturers for powertrain systems will welcome this new competitor in the marketplace for its affordable price, high technology, productivity, quick delivery, and domestic support,” said Adam Gimpert, President of Helios. This line, called “NEO Power Skiving” or “NEOPS,” is the latest affordable innovation brought to the North American market by Helios. Helios Gear Products announces a new line of machine tools from YG Tech that serves gear manufacturers seeking a power skiving solution.

0 kommentar(er)

0 kommentar(er)